🧠

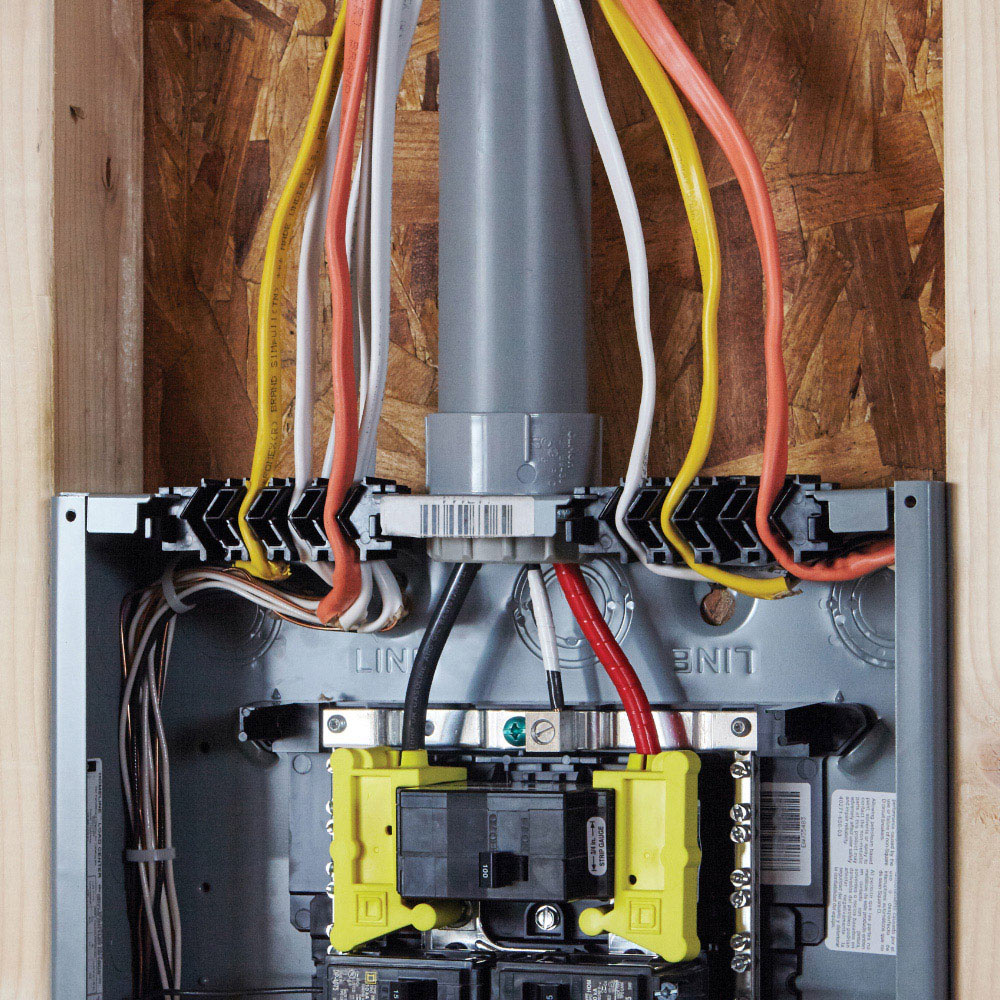

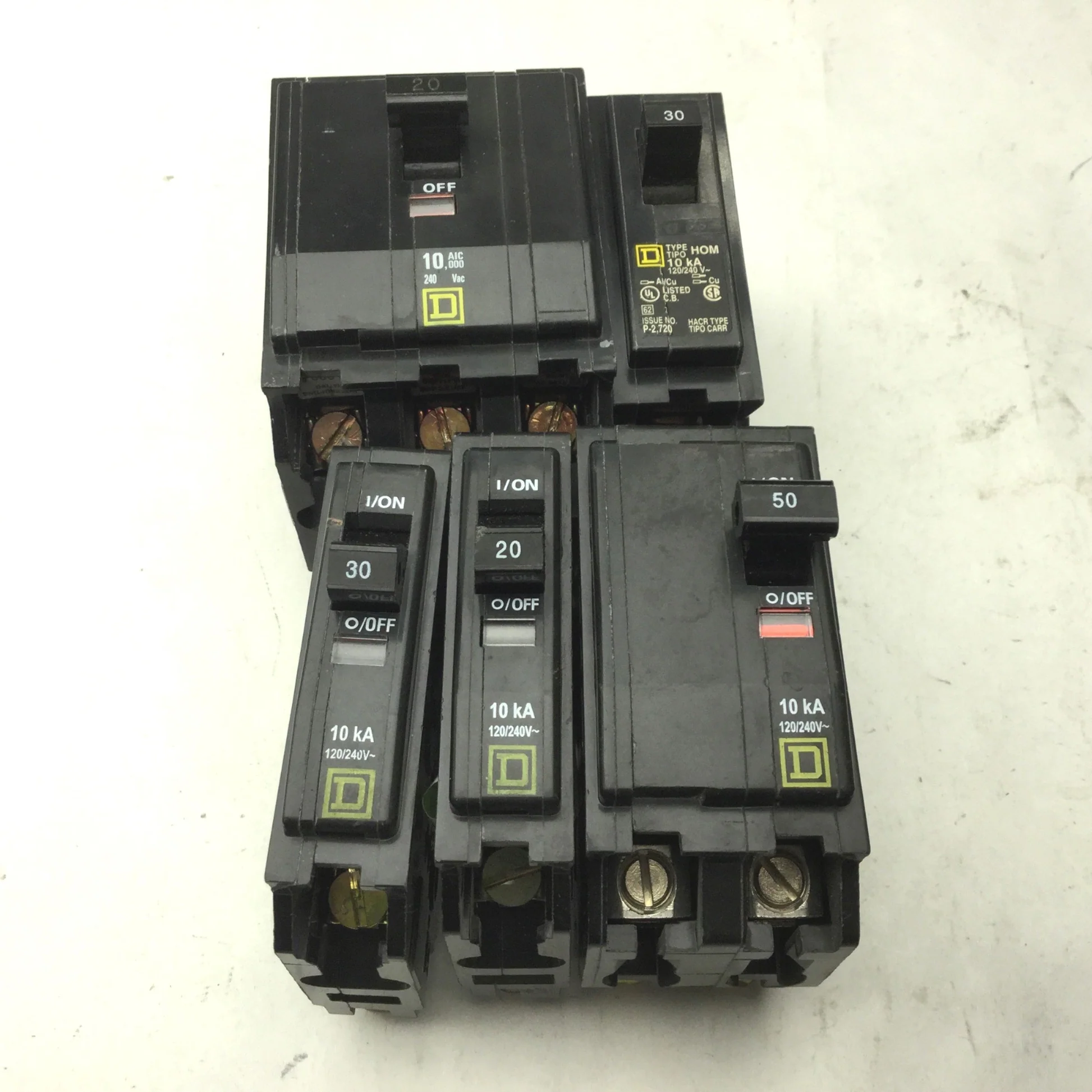

240 — Overcurrent Protection Basics

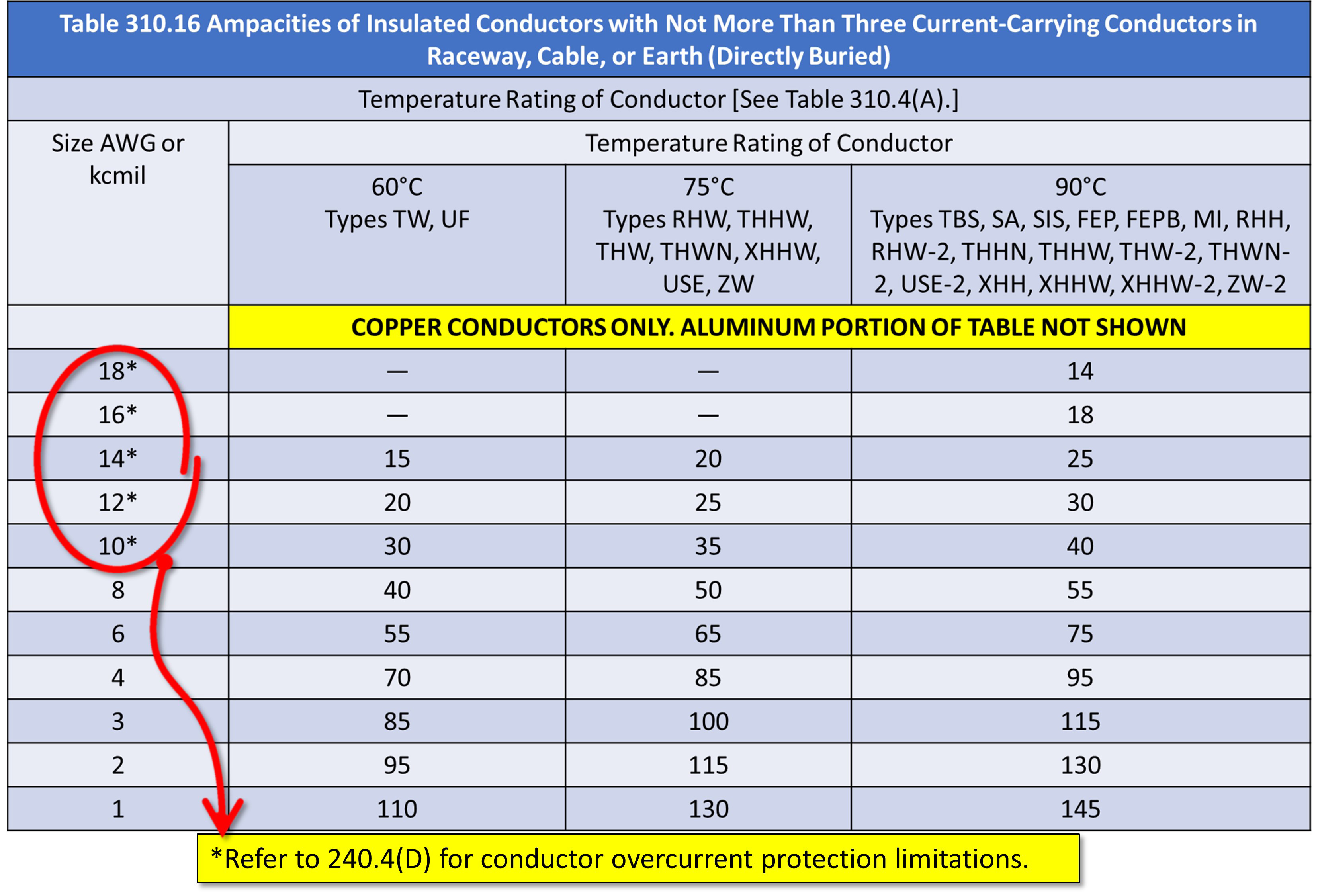

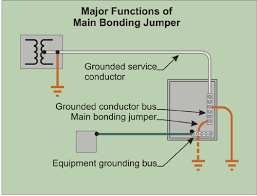

- 240.4Conductors must be protected per their ampacity. Small conductor rules are not blanket allowances—only certain sizes (14, 12, 10 AWG) can round up when allowed.

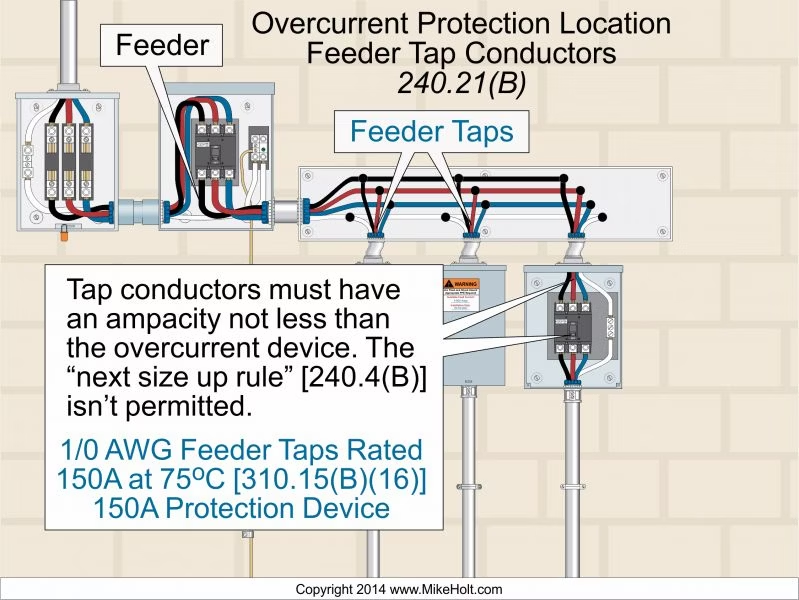

- 240.21Tap conductors: 10-ft, 25-ft, and feeder tap rules all differ. Each has conditions (length, termination, protection) that must all be met. Examiners love to mix them.

- 240.6Standard breaker sizes: 15, 20, 25, 30, 35, 40... If you see 45A or 55A, that's not standard—use next standard size rules only when another Code article permits.

- 240.10Protective devices can't be used as switches unless they're identified for that function. That includes many breakers—but check the marking.

EXAM TRAP

NEXT SIZE UP

240.4(B) doesn’t apply to every circuit. It’s limited to specific small conductor cases. If a question asks about rounding up on #2 AWG, the answer is no.

Memorize standard ratings and the exceptions for rounding up.

Tap rules = strict length and protection requirements.