🧭

300 — General Requirements for Wiring Methods

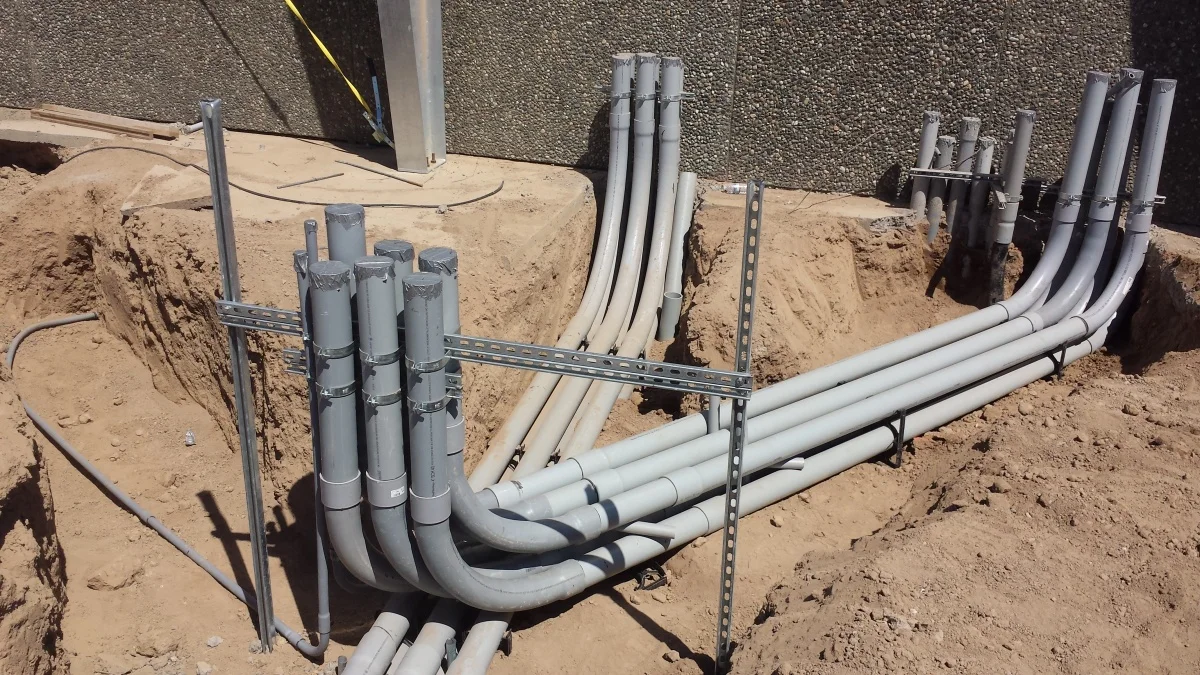

- 300.4/5Protection from physical damage; burial depths vary by method and occupancy.

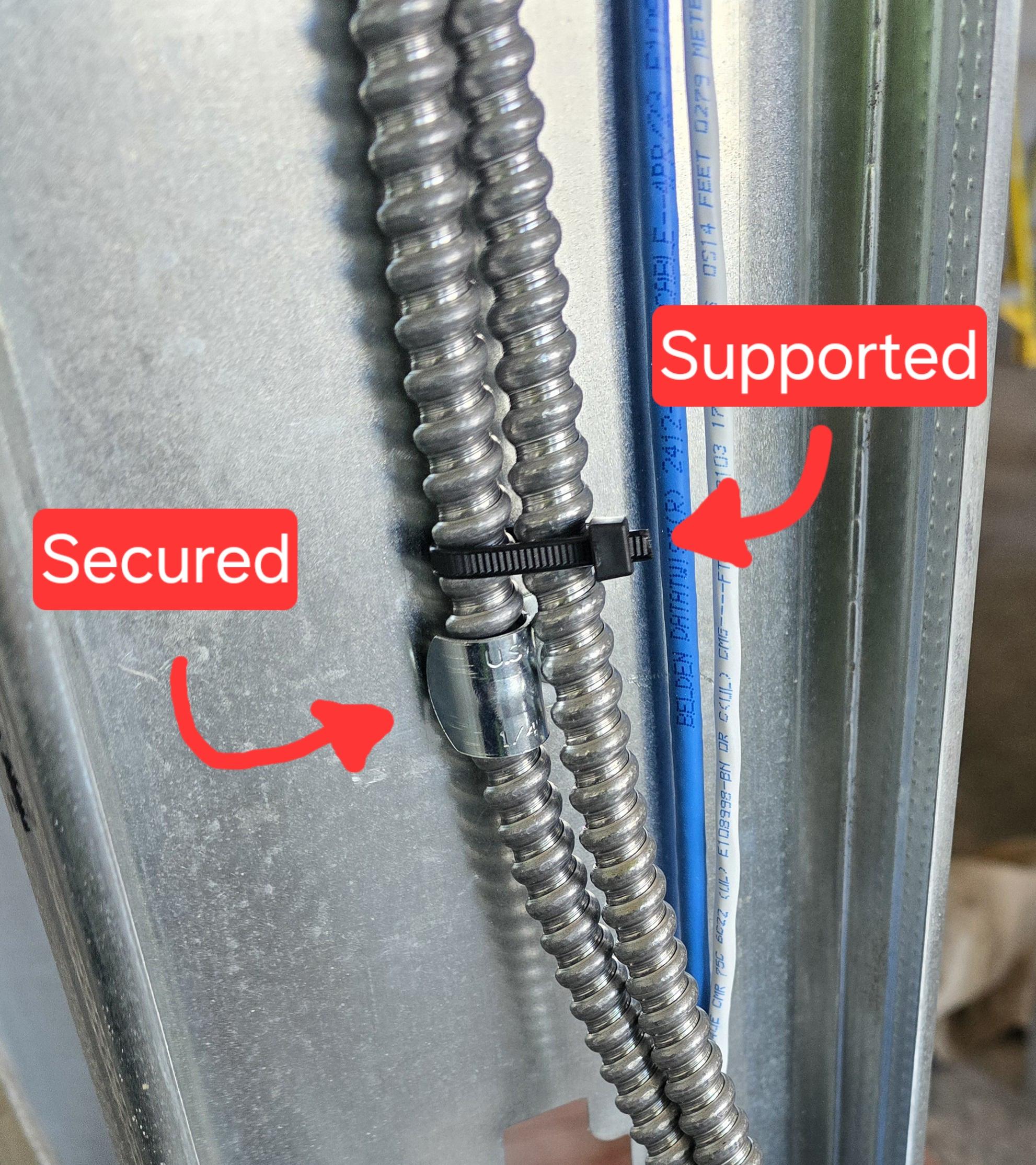

- 300.10Metal raceways must be electrically continuous and effectively bonded.

- 300.15All splices/terminations in boxes or fittings—no loose splices in raceways.

- DamageProtect wiring methods from physical damage; add sleeves/guards where exposed to abuse.

- FittingsUse listed fittings for the wiring method; don't mix EMT and RMC fittings.

EXAM TRAP

Location governs method

Dry vs damp vs wet changes everything: allowed methods, fittings, and conductor ratings. Identify the space first; choose the method second.

Method changes when the environment changes.

Maintain a continuous fault-return path.