🧯

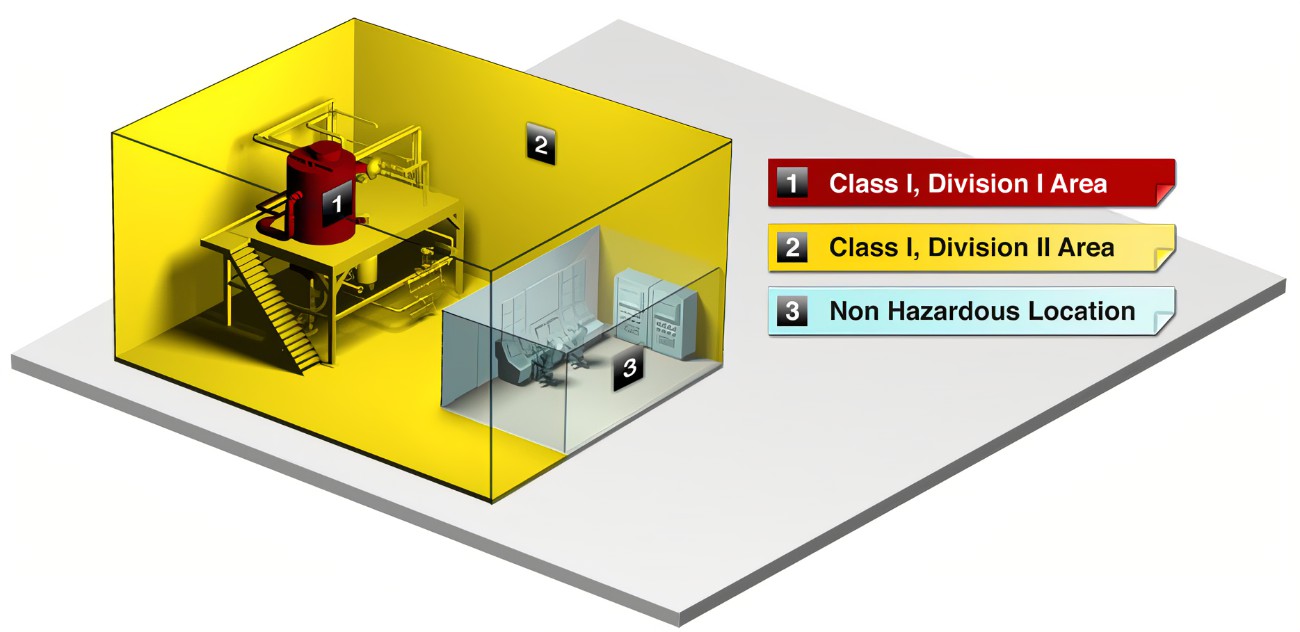

Art. 500/501 — Classified Locations: Classes & Divisions

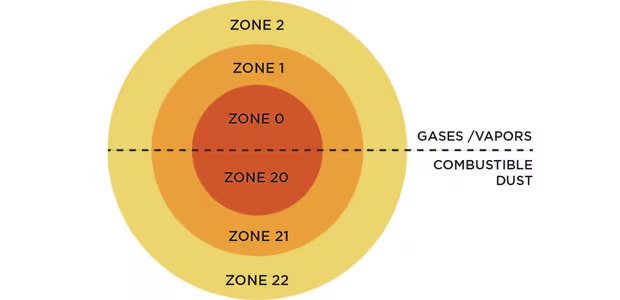

- Class IFlammable gases/vapors. Div 1 = normal presence; Div 2 = abnormal (leaks only).

- Class IICombustible dusts (grain/metal). Same Div 1/2 concept.

- Class IIIIgnitable fibers/flyings—surface accumulations & handling areas.

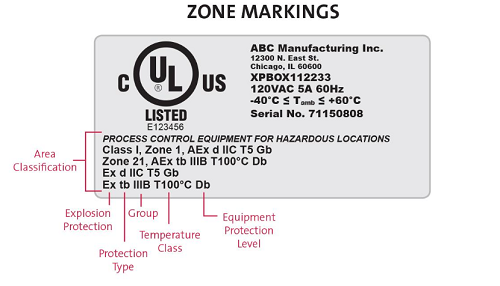

- SelectionEquipment must be identified for class/division & group; seals, enclosures, wiring methods vary accordingly.

- 501.15Sealing requirements: install explosionproof seals where required at boundaries and where the wiring method demands it—placement follows 501.15 notes.

- T-CodesEquipment temperature codes (T-ratings) must be suitable for the ignitable material—verify against the area's gas/dust group and temperature class.

EXAM TRAP

Class vs Division

Class = material type (gas/dust/fiber). Division = likelihood (1 = normal, 2 = abnormal). Don’t mix them.

Identify Class **and** Division before selecting gear.

Seal placement follows listing & code notes.