🪧

Art. 600 — Electric Signs & Outline Lighting

- 600.5(A)Provide a dedicated branch circuit (typically 20A, 120V) to each sign/outline lighting system—no other loads permitted.

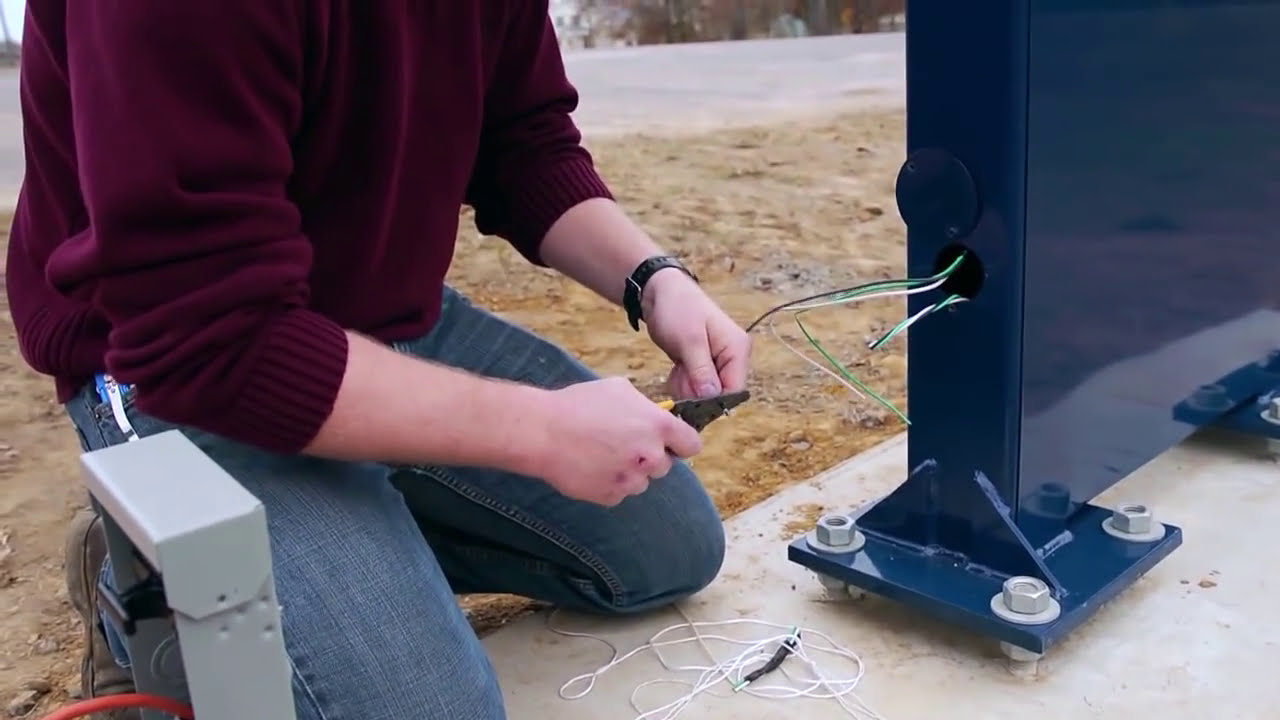

- 600.6(A)(1)A readily accessible disconnect must be within sight of the sign or outline lighting system unless exceptions apply.

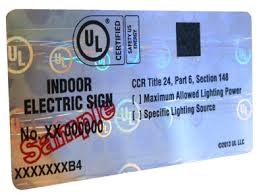

- 600.3All sign equipment must be listed/identified and installed per the label and instructions (mounting, conductors, environmental limits).

- 300/600 blendFollow Chapter 3 wiring method rules; use wet/damp-rated fittings where exposed to weather.

- Grounding/BondingBond metallic sign enclosures and raceways; maintain a low-impedance fault path back to the source.

EXAM TRAP

If it’s a sign circuit, it’s dedicated. Don’t add receptacles/lighting. Disconnect must be within sight unless a permitted exception is met.

Local disconnect: labeled and readily accessible.

Use listed components and follow markings.